Portfolio

Services

Consulting

Forming the basis of our consultancy work is an exhaustive analysis of your current situation and needs, from which we then devise bespoke solutions for you.

System Engineering

A system always interacts with its environment, so for us system engineering doesn’t simply end at the physical boundaries of a product. Our approach and development activities are interdisciplinary and we see ourselves as part of an overarching system.

Prototype Construction

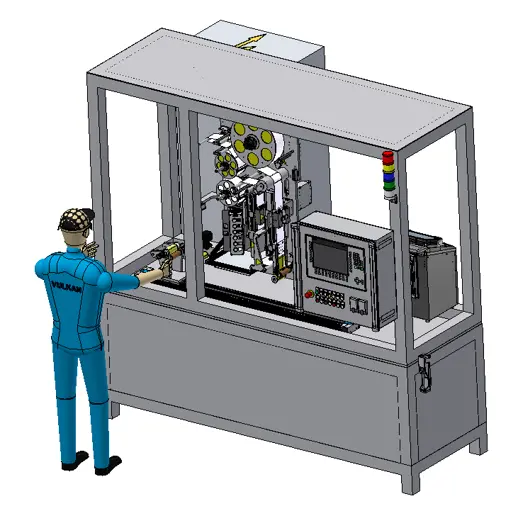

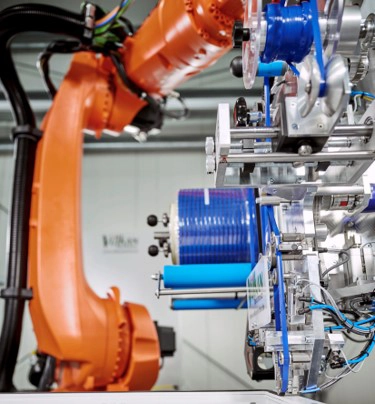

New technologies not only promise enhanced performance but are always fraught with significant technical risks too. Working in collaboration with Vulkan Technic GmbH, we can create prototype systems for you to demonstrate the production capabilities of a new technology.

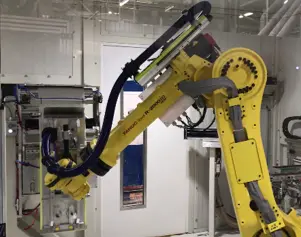

Design and Construction of Special-purpose Machines

With the help of the team of experts at Vulkan Technic GmbH, we will ensure efficient and goal-directed implementation into design and work plans of the concepts formulated in the initial stages. System execution is likewise carried out at the Wiesbaum site of Vulkan Technic GmbH.

Concept Development

Concept development involves carefully examining the technical boundary conditions for new manufacturing processes, modules and components. We map out variant comparisons, benchmarks and concept designs for individual processes or entire manufacturing areas, thereby translating our customers’ ideas into viable solutions.

The Future? We Can!

Our wide variety of bonding techniques means we can bond all the common types of battery cells.

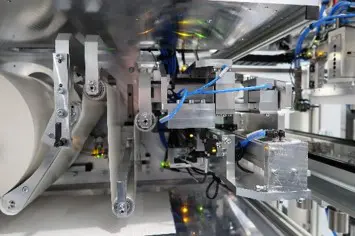

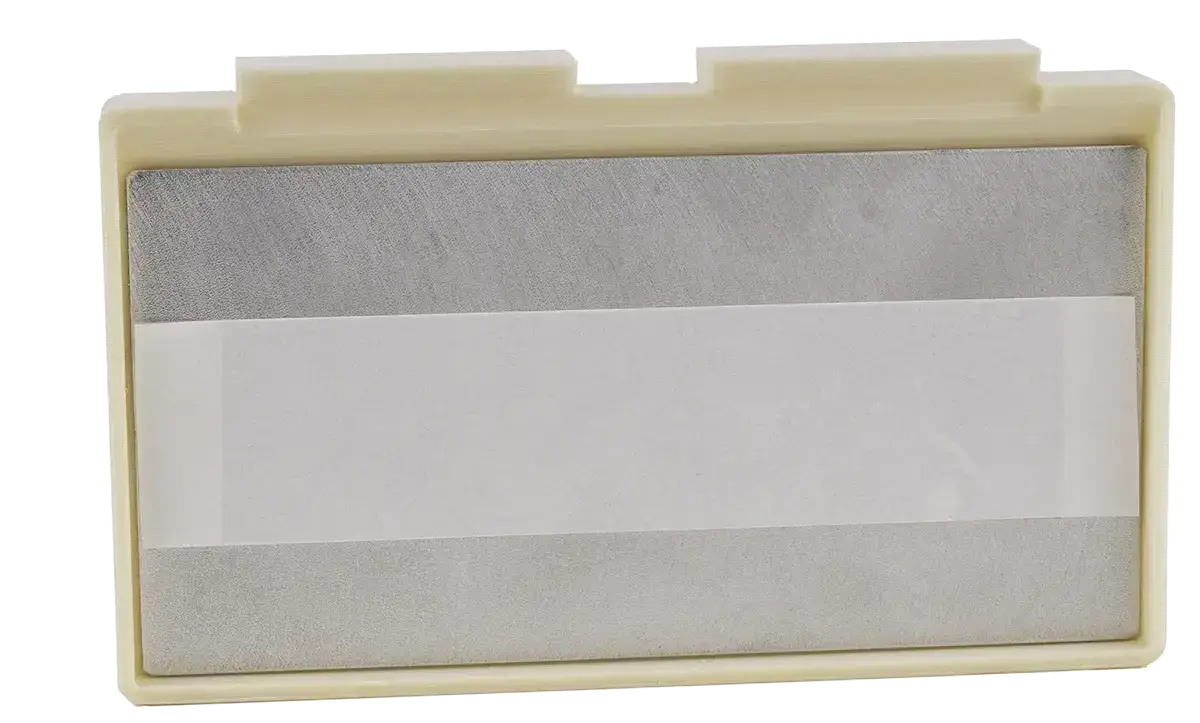

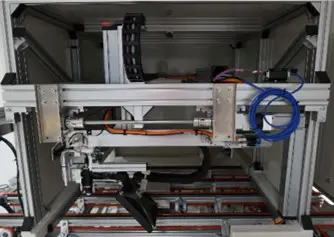

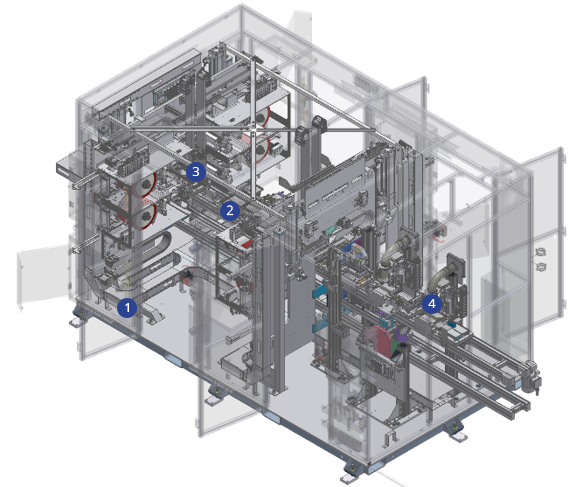

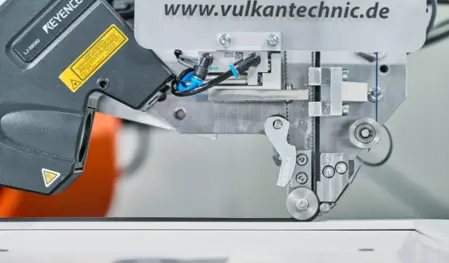

Applying double-sided adhesive tape in cell frames:

The machine is used to stick double-sided adhesive strips into a cell frame. The product is bonded on both sides. Thanks to the tandem pressing cylinder, it was possible to achieve a cycle time of less than 5 seconds.

- Unwinding cutter

- Turnover station

- Application unit

- Liner removal

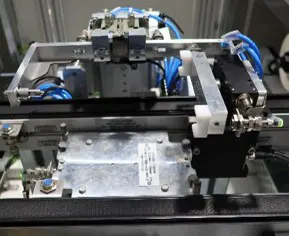

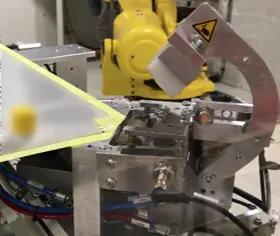

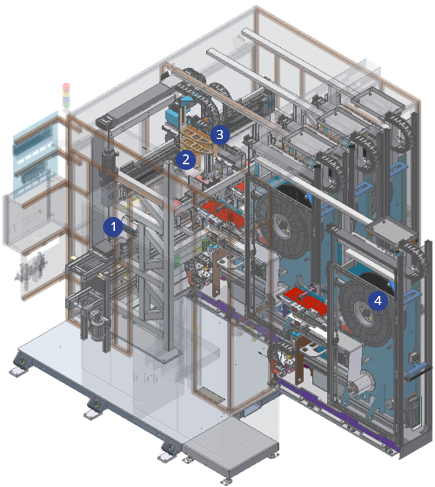

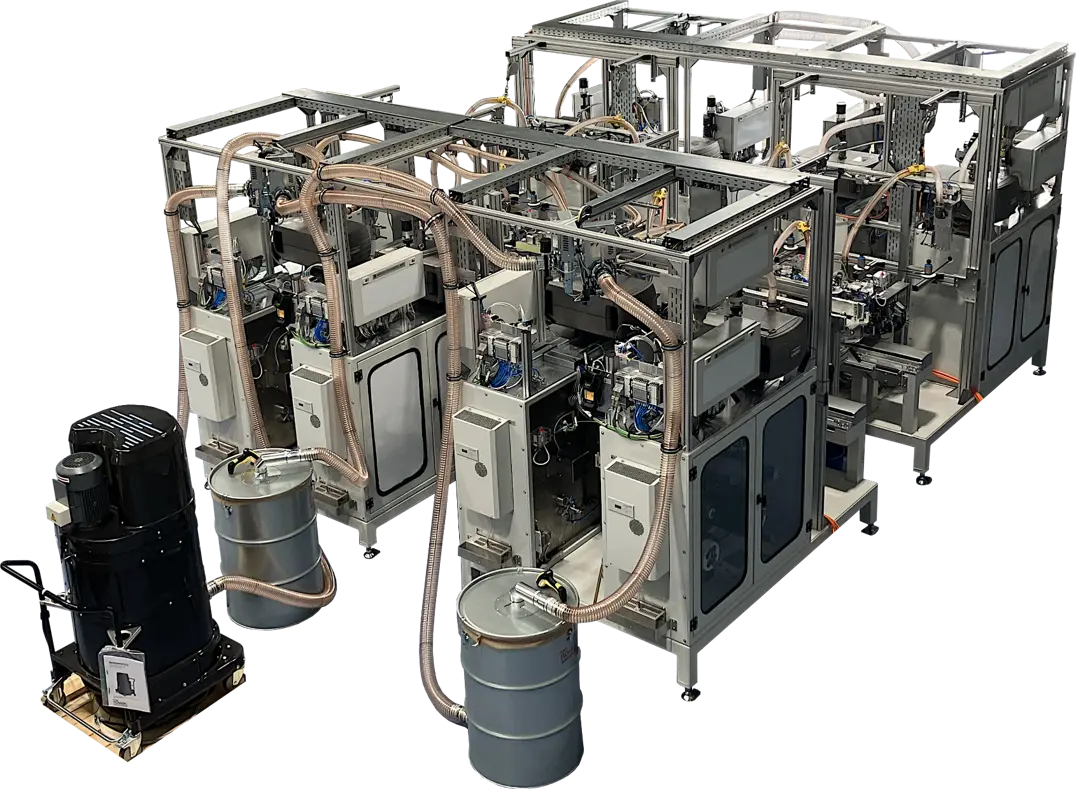

Applying compression pads on to pouch cells:

The machine is used to apply compression pads on to pouch cells. The adhesive pads are taken from the dispenser and applied on to the pouch cell. Thanks to redundant applications systems, it was possible to ensure system autonomy and continuous production.

- Surface cleaning

- Application gripper

- X/Y/Z portal

- Adhesive tape dispenser

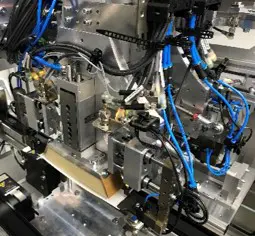

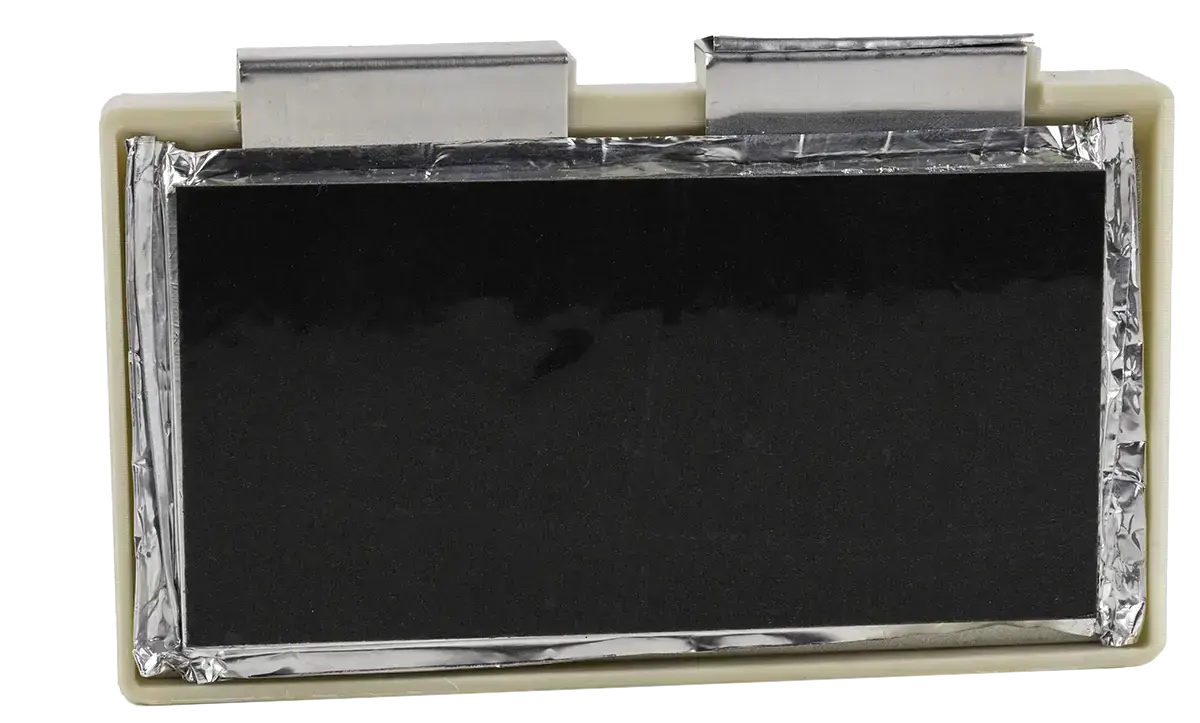

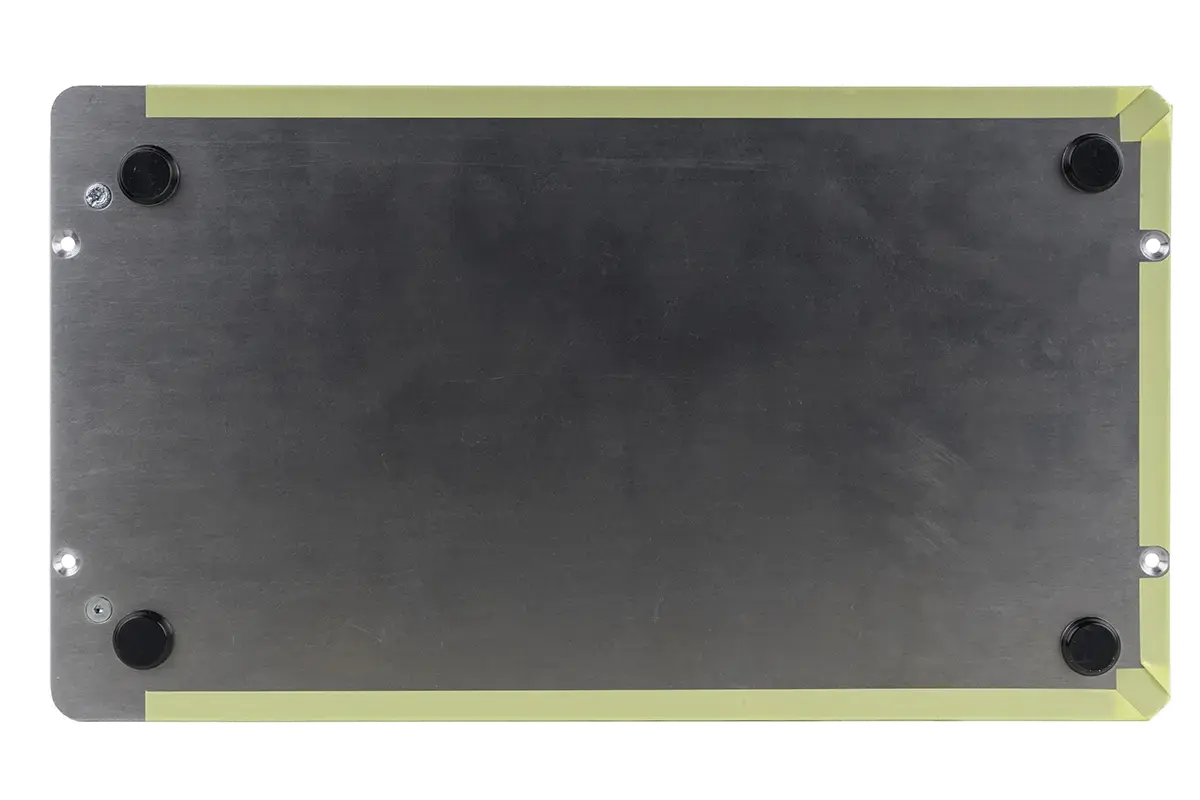

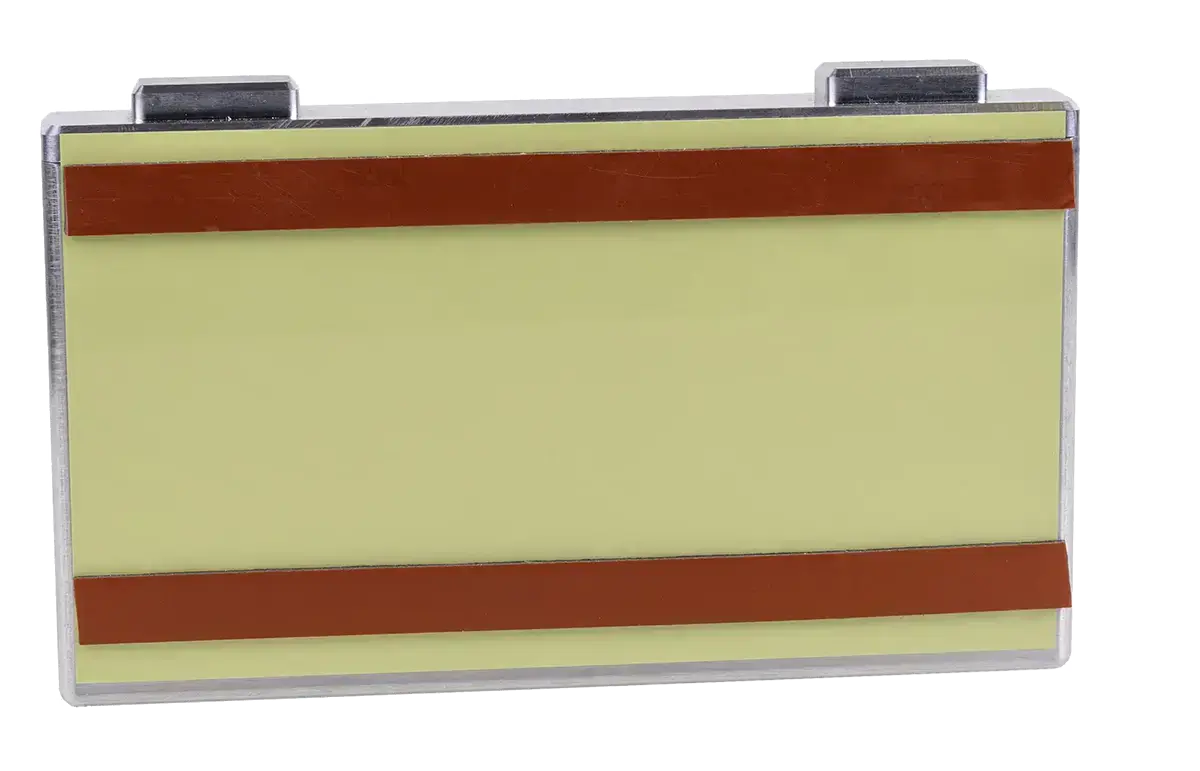

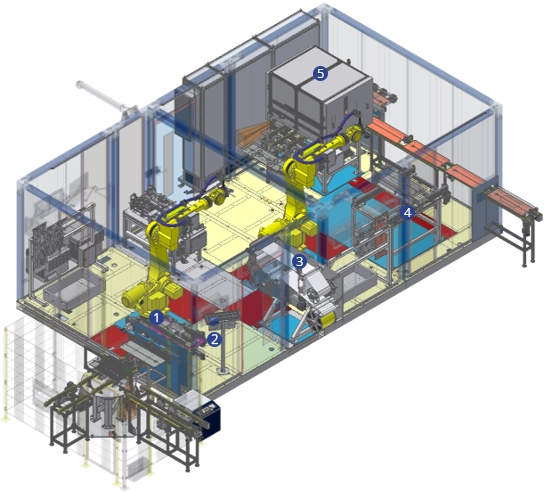

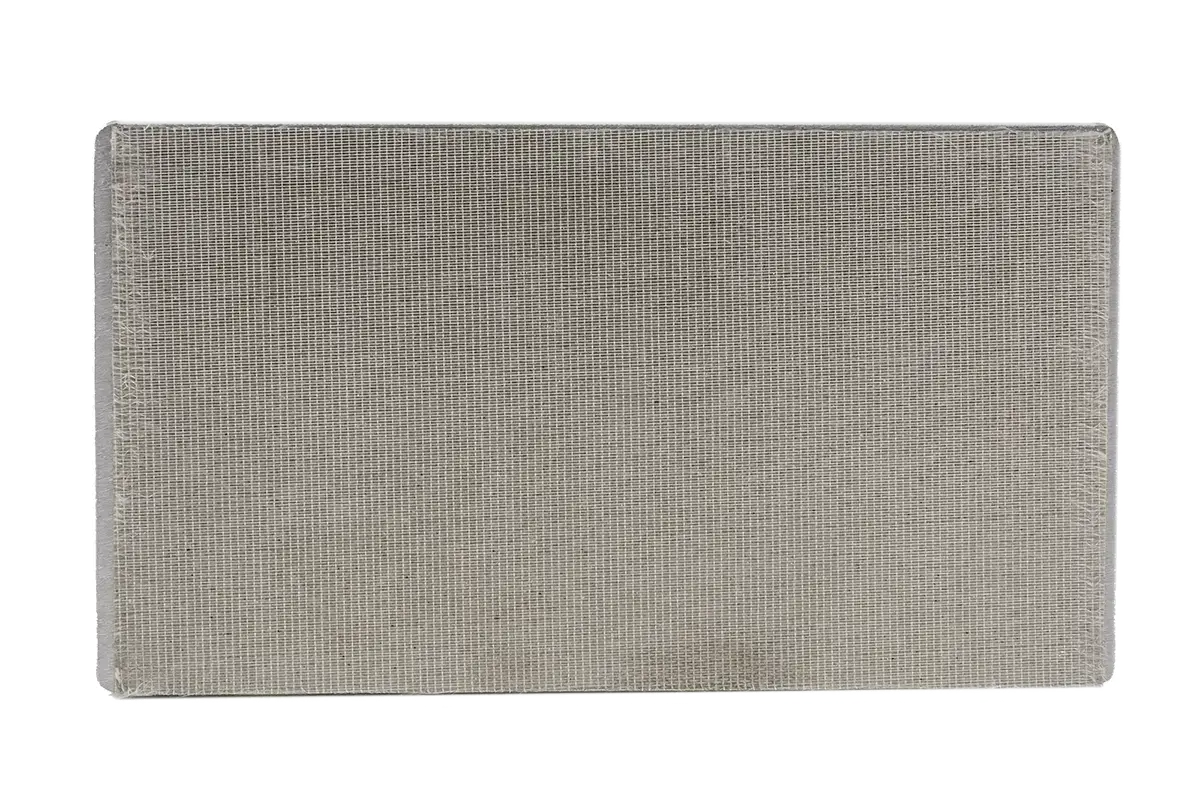

Spacer bonding on to prismatic cell:

Using the 8 vacuum bonding heads and 8 unwinding units, the prismatic cells are bonded with an acrylic foam spacer.

By doubling the stations, a cycle time per cell of less than 1.5 seconds is achieved.

Bonded prismatic cell

Cylindrical cell bonding with insulation film:

A technique for bonding cylindrical cells was developed for a noted German OEM.

Bonded cylindrical cell

Scroll down for more interesting projects

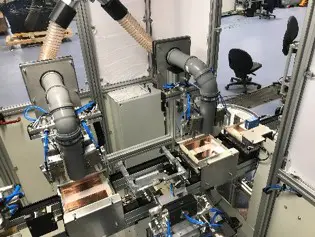

Applying insulation film on to a battery cooler:

The system is used to apply insulation film on to battery coolers. The film is folded over at the edges of the component and the cooler is subsequently checked in a test station to make sure it is free of bubbles and then discharged. The bonding heads we now use allow us to apply a film width of up to 700 mm.

- Product handling

- Surface cleaning

- Film application

- Folding station

- Test station

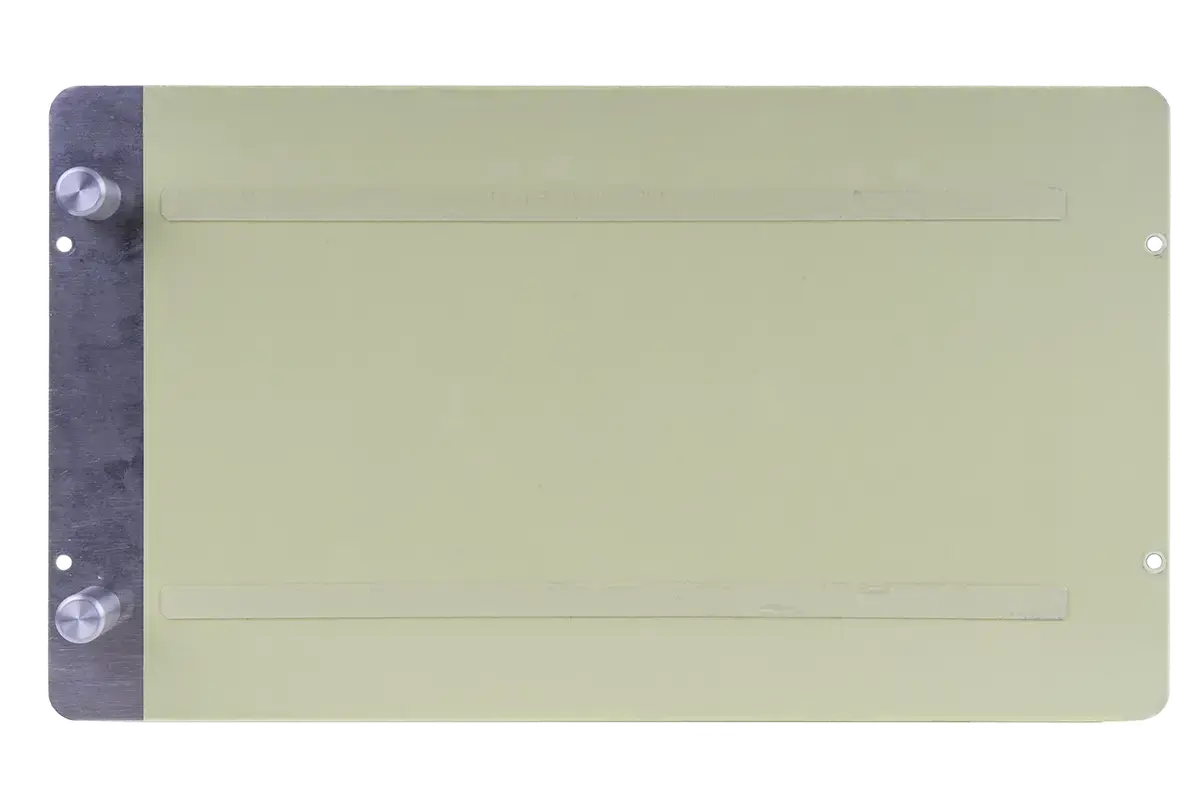

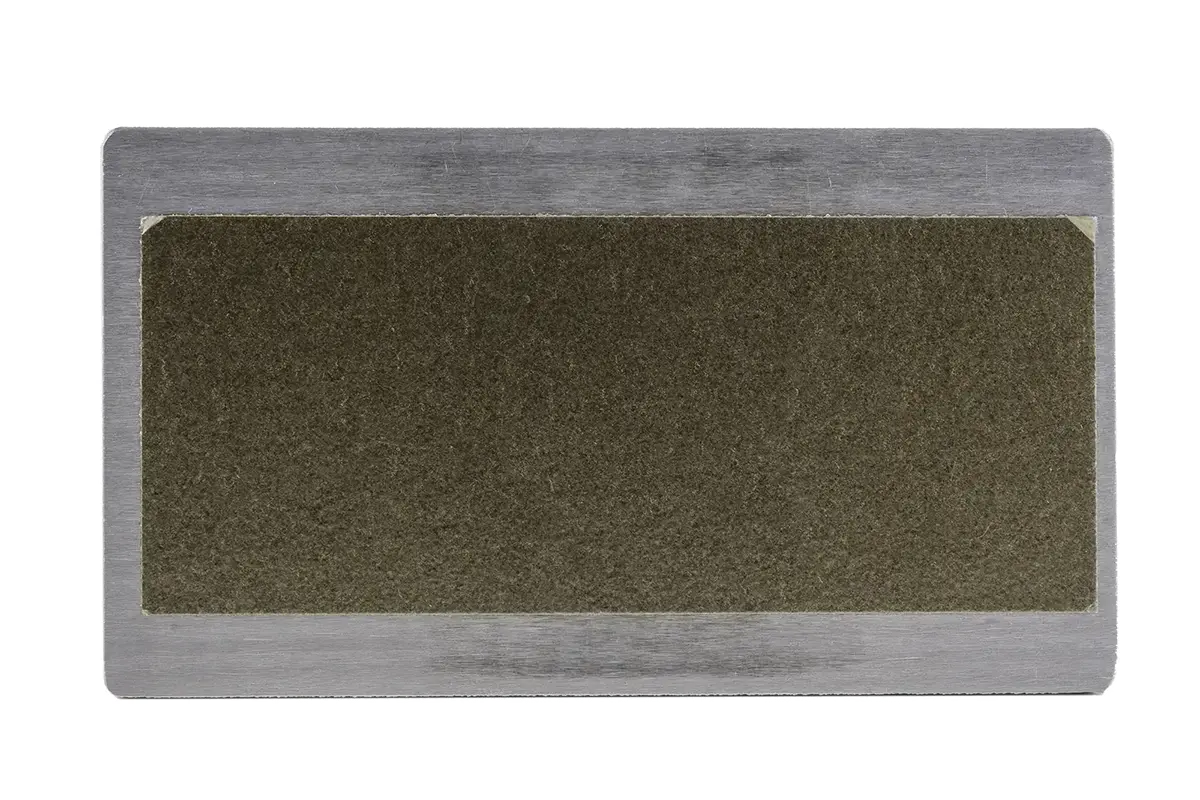

Applying tapes to tie rods or side plates of battery blocks:

By employing various machine concepts we can bond the plates with insulation film or with acrylic-foam adhesive strips.

Bonded side panel

Applying heat-resistant films (mica films):

By employing various machine concepts we can apply heat-resistant films to battery inserts or side plates.

Bonded inserts

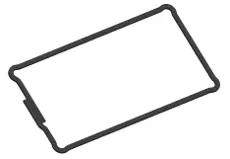

Mobile bonding head

With our mobile bonding head we are able to apply a wide variety of seals on to battery covers or battery housings.

Battery seal

Bonding head

References

From job-lot production to large-scale manufacturing, from start-ups to concerns operating globally – we are solution providers covering both national and international markets. You can see a selection of our satisfied customers here.

Contact Us

Feel free to contact us – we’ll be happy to help you.

Vulkan Engineering GmbH

Johannes-Kepler-Str. 8

54634 Bitburg

Phone: +49 6561 67039 0

E-Mail: info@vulkan-engineering.de

Contacts

Andreas Thiex

Site management / Project management for battery automation

E-Mail: a.thiex@vulkan-engineering.de

Phone: +49 6561 67039 10

Franz-Josef Tines

Team leader construction

E-Mail: fj.tines@vulkan-engineering.de

Phone: +49 6561 67039 12